the BOWL

the BOWL : week two

purpose :

to use a combination of 'stretching' and 'shrinking' to create a hemispherical form.

application :

the skills learned in this exercise will help us in forming the basic 'ballooned' shape of the fuel tank.

tools :

● laser cut template ● laser cut radius gauge ● curved stump ● nylon mallet ● sand bag ● round dolly ● sanding board ● planishing hammer ● metal polish (Brasso) ●

steps :

For the Shape:

1. Circumference template is made on illustrator by drawing 4 circles at equal increments with the same center point2. Drawing is then laser cut into a 3mm ply sheet

|

| LASER CUT TEMPLATE. Outer rim marks the shape of bowl to cut out. Inner rims mark the dent points for stretch and pull technique. |

3. Cut a square of aluminum so the largest circle fits within

4. Nest all circles together and place on aluminum square

5. Using a thin marker, trace around the inside of the smallest circle

- Be careful here as the marker will smudge. The lines need to be visible till the basic curved shape is formed

7. Using tin snips, cut the aluminum square along the largest drawn circle

- Try to cut on the outside of the circle and slowly trim down to the drawn circle to avoid accidentally cutting away too much material. If you have don't worry too much as this can always be rectified by trimming down more after the bowl is formed or sanding down.

9. Using the pointed end of the nylon mallet, gently hit around the second largest drawn circle to form a dent

- It may take a couple hits to get the aim right. Don't worry to much if the dents aren't on the line as this can be smoothed out with the flat end of the mallet

11. Continue this process of denting and smoothing out for the full way around each of the circles

12. Once this process is complete, the 2d circle should now be a shallow bowl form

13. This process can be repeated till the desired curve is achieved (note: use the radius gauge to ensure the whole bowl follows the same curve)

14. Once the bowl has reached the desired curve, place it on the sand bag and using the flat end of the nylon mallet, hit the inside of the bowl to smooth out the lumps

15. Insert a wheel into the English Wheel (the right wheel will depend on how curved the bowl is)

16. Wind the wheel up till there is approx 1.5mm between the top wheel and the bottom wheel

17. Feed the edge of the bowl between the wheels and roll the bowl back and forth, slowly working around the full circumference of the bowl

18. Once the bowl feels smooth, adjust the wheel so the space between the top and bottom is smaller

19. Continue to roll the bowl and then adjust the wheel till the bowl achieves a completely smooth curve (note: it is recommended to adjust the wheel in small increments to ensure the 'distribution' of material is even through the bowl)

20. The final step for the shape is to sand down the edge of the bowl on a table sander (note : a metal file can also be used but this usually won't be able to achieve a smooth finish around the full circumference)

For Aesthetics:

1. Using a round dolly which suits the curvature of the bowl, hammer the outside of the bowl to achieve the 'hammered' look (note : gentle hits are recommended to avoid damaging the shape of the bowl) and continue till the desired look is achieved

- This step does require patience and focus. If the hammer hits the bowl at a slight angle it could mark the aluminum

2. Use a scrap cloth or paper towel and apply the Brasso metal polish to the outside of the bowl till desired shine is achieved

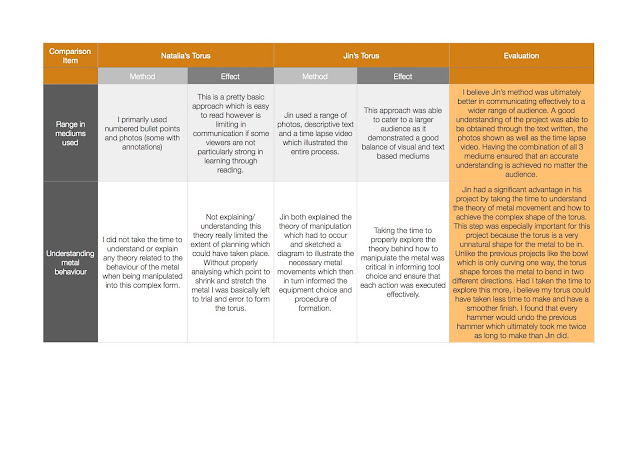

general notes/reflection : I think this exercise was really critical in introducing the idea of 'shrinking' and 'stretching' the material to form curved shapes. The hardest part of this exercise for me was in distributing the material evenly throughout. The curvature of the bowl was fairly simple to achieve but my finished bowl still has thick and thin areas of metal which are especially apparent around the circumference of the bowl.

Comments

Post a Comment